Total Gas & Cylinder Management:

| Atmospheric Products and Services (APS) offers a number of value-added services and programs that will enable your organization to become more profitable. Our broad expertise and know-how in total gas and cylinder management programs, drawn from many years as a world-leading gas and equipment supplier, is apparent to our customers. Atmospheric Products and Services (APS) welcomes the opportunity to work with you and provide your organization with the proper custom service solutions.

The ACCURA® Cylinder Tracking System is a PC-based customer version of our cylinder tracking system to assist in the management and billing of these assets and to reduce the occurrence of lost cylinders. The greatest savings garnered with this system are with the audit processes, reduction of materials, and historical data collection. ACCURA® can generate location balances, hazardous materials reports, purchase orders, expired cylinder reports, cylinder history, transaction history, gas cost and rental reports. This asset control tool can also be expanded to include other procured products and inventories. The benefits of ACCURA® are: * Identifies Customer Utilization & Consumption and Eliminates Stagnant Gases & Unneeded Inventories *Reduces Billing Errors *Cost Savings experienced through Increased Cylinder Accuracy, Simplification and Reconciliation of Balances to Invoices, Billing to Departments Separately for Gas Usage, and Detailed Reports and Analysis * Reports Available: Location Balances, Purchase Orders, Expired Cylinders, Cylinder History, Transaction History, Gas Cost and Rent, and Hazardous Material Inventory

|

|

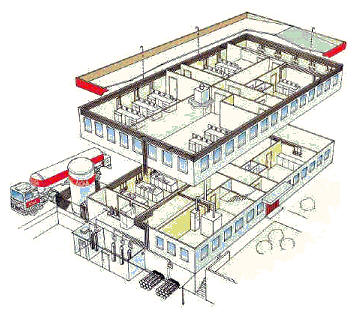

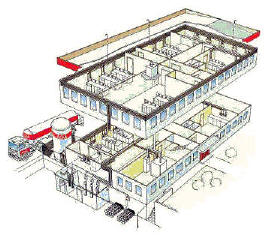

Central Gas Supply: New and existing buildings and laboratories alike can be fitted with a centralized gas supply system. Where possible, Atmospheric Products and Services (APS) strives to implement this type of gas supply scenario. The main benefits are:* Improved Operating Income - A continuous gas supply system to each workstation means less wasted time and fewer unplanned disruptions for changing gas cylinders. Fewer and larger modes of supply, means more effective emptying of the cylinder which in turn give lower costs for gas and cylinder rental as well as transport charges. * Increased Safety - The risk of accidents is reduced as the need to handle gas cylinders inside the work place is minimized. * Better Working Environment - The workplace can be designed more appropriately to optimize the scientists’ time and operations. Outlets positions at every work station are convenient, fast, and easy to use. |

|

|

|

| Gas Distribution Systems The Atmospheric Products and Services (APS) Specialty Gas Equipment Group specializes in the design, fabrication, and installation of custom gas manifolds and complete distribution systems. Our systems are designed using the latest technologies, follow the latest codes and standards, and meet applicable regulatory requirements. We provide documented systems complete with operating procedures and maintenance recommendations. Once designs are finalized, we fabricate the systems and can install the systems on-site. Atmospheric Products and Services (APS) Gas offers many services to assist with the specialty gas distribution system design. These include: * Facility/Laboratory Gas Distribution Layout * Central Gas Supply Consulting and Design * Specialty Gas Equipment Needs Assessments * Determine Contamination/Impurity Level Requirements and Recommend Material Selection – (both Equipment and Piping) * Detailed Equipment Specification and Sizing * Safety Consulting, Training and Safety Management Review * Site Audits and Process Review for Government Compliance, cGMP, FDA The Atmospheric Products and Services (APS) Specialty Gas Equipment Group specializes in the design, fabrication, and installation of custom gas manifolds and distribution systems. Our systems are designed using the latest technologies, follow the latest codes and standards, and meet applicable regulatory requirements. We provide documented systems complete with operating procedures and maintenance recommendations. Once designs are finalized, we fabricate the systems and can install the systems on-site. Atmospheric Products and Services (APS)offers many services to assist with the specialty gas system design. These include: * Facility/laboratory gas distribution layout *Central gas supply consulting and design * Specialty gas equipment needs assessments * Material selection – (both equipment and piping) * Detailed equipment specification * Equipment sizing * Safety consulting and safety management review

|

|

Central Gas Supply - Increased Safety * The risk of accidents is reduced since there is no need to handle gas cylinders inside the work place * Only low-pressure equipment and small gas quantities are present in the work place * Gas cylinders are connected under one roof, which facilitates removal and safety management Central Gas Supply - Improved Operating Economy * A continuous gas supply to each work station means less wasted time and fewer unplanned disruptions for changing gas cylinders * Fewer and larger gas cylinders which together supply all users, means more effective cylinder management, which in turn gives lower costs for gas and cylinder rental as wellas transport charges Central Gas Supply - Better Working Environment * Outlets positioned at each work station are convenient and easy to ues * The work place can be designed more appropriately - better space management and ergonomics * Greatly reduced risk to personnel Central Gas Supply - Turnkey Deliveries * Specialty Gas Equipment Group has extensive knowledge in the gas industry and provides consultation during system design to installation and start-up * Design follows generally accepted codes, standards and practices |

|

|

|

| Product Application & Safety Training and Technical Support * Programs set up to assist customer comply with NFPA 45, 55 and 704 code requirements * Programs set up to assist customer comply with OSHA 29 CFR 1910.1200 regulations * Product Hazards and Equipment Safety Training * High-Pressure Cylinder Handling and Storage Training * Product Application and Equipment Operator Training * MSDS Overview |

|

|